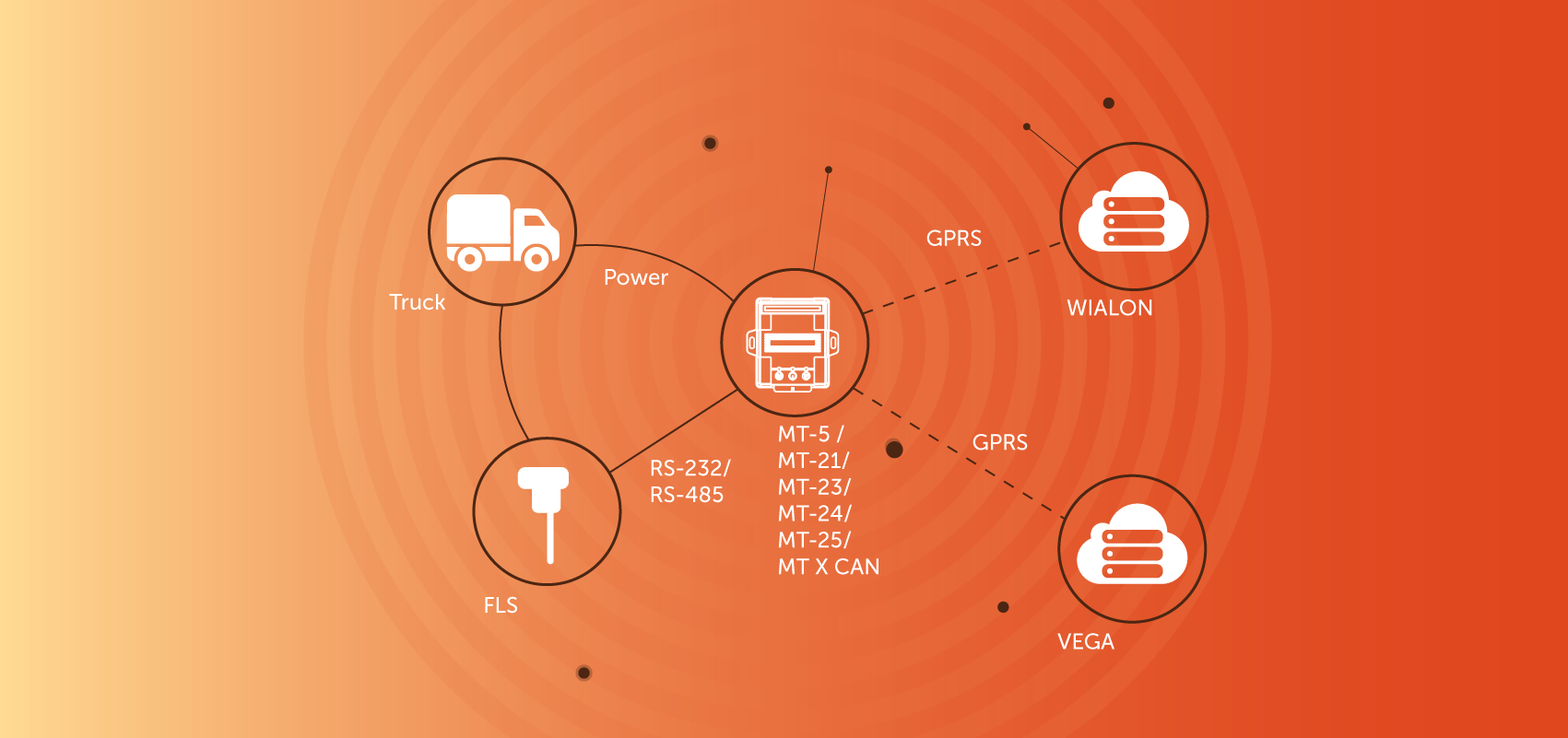

- Connect the FLS (fuel level sensor) to GNSS Tracker through the RS-232/RS-485 interface (via LLS protocol);

- Perform the FLS calibration in accordance with the manufacturer's instructions;

- Connect power from the on-board network to the GNSS Tracker;

- Configure the device and the cloud monitoring service (WIALON or any other, including your own);

- Now you can receive and process more accurate fuel level data on a cloud server than can be obtained from the CAN bus, keep more accurate statistics on fuel consumption and derive patterns, respond in time to cases of fuel theft.

Monitoring of truck placement and an enhanced fuel control

To implement the solution, you will need any of the devices with RS-232 or RS-485 interface. The devices have difference in additional functions, for example, the MT-25 device has voice support, and in the devices of the MT X CAN series a CAN-bus scanner is implemented to conveniently search for the necessary parameters for monitoring. When you have decided on the device, you must perform the following steps:

Vega MT-5

Vega MT-5 Vega MT X Int

Vega MT X Int Vega MT X Ext

Vega MT X Ext Vega MT X LTE

Vega MT X LTE Vega MT-21

Vega MT-21 Vega MT-25

Vega MT-25 Vega M100

Vega M100 Vega M110

Vega M110 Vega M50

Vega M50 Vega M410

Vega M410 Vega MX600L

Vega MX600L Vega MX500

Vega MX500 Vega MX810

Vega MX810 Vega RK-2.4

Vega RK-2.4 Vega SM-1

Vega SM-1 Buttons

Buttons Indicators

Indicators Vega ST-1

Vega ST-1 Vega SD-1

Vega SD-1 GLONASS/GPS Antennas

GLONASS/GPS Antennas GSM Antennas

GSM Antennas Connectors with Wires

Connectors with Wires Vega K-232

Vega K-232 Vega SA-1

Vega SA-1 Vega RP-1

Vega RP-1 Destination Display Boards

Destination Display Boards Vega BLE module

Vega BLE module Vega MT-5

Vega MT-5 ESCD

ESCD