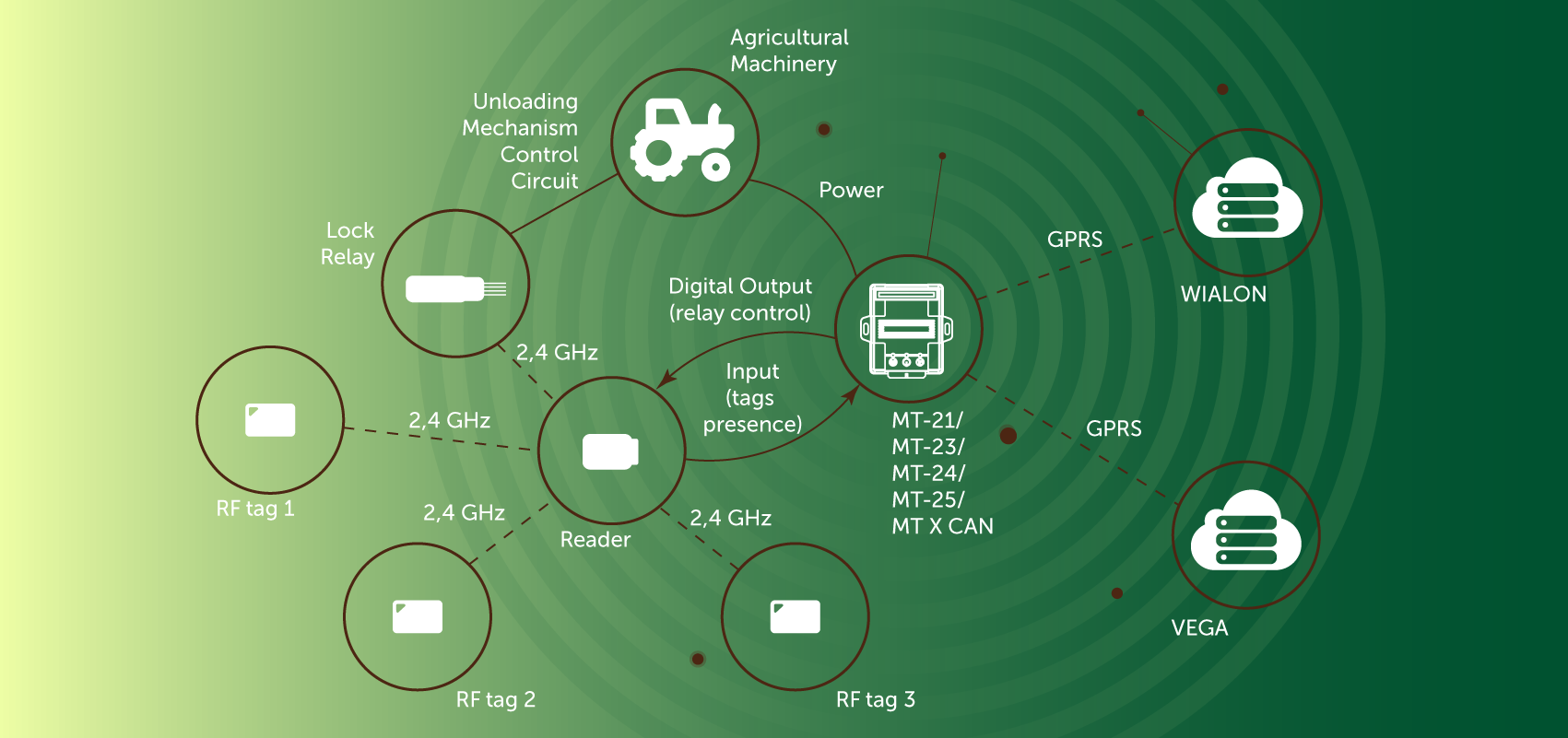

- Connect the RF tag reader to GNSS Tracker;

- Place RF tags at the places intended for unloading (for example, an unloading terminal, a truck for transporting grain);

- Connect the wireless locking relay to the GNSS Tracker and break the control circuit of the mechanism which is needed for unload activation (for example, unloading pipe, transporter belt, truck side lock, hydraulic drive, etc.);

- Configure a script in the device settings that blocks the unloading mechanism until it detects the presence of a registered RF tag in the receiving radius;

- Connect power from the on-board network to the GNSS Tracker;

- Configure the device and the cloud monitoring service (WIALON or any other, including your own);

- Now you can automatically block unregulated unloading of equipment at the physical level (theft of raw materials). In case of urgent need, it is possible to reconfigure the system and manually allow unloading at a point not equipped with RF tags (for example, if you urgently need to unload in a non-tagged contractor machine).

Monitoring of agricultural machinery placement and a ban on unloading in the wrong place with the use of locking relays and RF tags

To implement the solution, you will need any of the devices with digital output and multifunctional input and the radio complect RK-2.4 (RF tag reader, RF tags, wireless locking relay). The devices have difference in additional functions, for example, the MT-25 device has voice support, and in the devices of the MT X CAN series a CAN-bus scanner is implemented to conveniently search for the necessary parameters for monitoring. When you have decided on the device, you must perform the following steps:

Vega MT-5

Vega MT-5 Vega MT X Int

Vega MT X Int Vega MT X Ext

Vega MT X Ext Vega MT X LTE

Vega MT X LTE Vega MT-21

Vega MT-21 Vega MT-25

Vega MT-25 Vega M100

Vega M100 Vega M110

Vega M110 Vega M50

Vega M50 Vega M410

Vega M410 Vega MX600L

Vega MX600L Vega MX500

Vega MX500 Vega MX810

Vega MX810 Vega RK-2.4

Vega RK-2.4 Vega SM-1

Vega SM-1 Buttons

Buttons Indicators

Indicators Vega ST-1

Vega ST-1 Vega SD-1

Vega SD-1 GLONASS/GPS Antennas

GLONASS/GPS Antennas GSM Antennas

GSM Antennas Connectors with Wires

Connectors with Wires Vega K-232

Vega K-232 Vega SA-1

Vega SA-1 Vega RP-1

Vega RP-1 Destination Display Boards

Destination Display Boards Vega BLE module

Vega BLE module Vega MT-5

Vega MT-5 ESCD

ESCD